An important element of our technology education is the hands-on experience which the students receive in the laboratory and workshop environment. The laboratories and workshops are equipped with adequate facilities to help students become productive immediately after graduation. Mainly these are:

Fluid Mechanics Laboratory

The facilities in the lab reinforce knowledge in such basics as fluid properties, hydrostatics, flow metering, and losses in pipes and fittings, etc.

Thermodynamics and Heat Transfer Laboratory

Facilities in the thermo-fluid lab allow hands-on experience in various temperature-measuring devices; studies in thermodynamic properties of gases, air standard cycles, heat transfer by conduction, convection and radiation, and performance characteristics of different types of heat exchangers.

Mechanics Laboratory

This laboratory is equipped with bench top facilities to enable experiments in a wide range of basic engine mechanisms such as governors, cams, gears; static and dynamic balancing; static and dynamic friction; forced and free vibrations, etc.

Fluid Power Laboratory

A number of oil power hydraulic trainers complete with modern industrial components provide expanding insight into the way in which these components function interactively in industrial oil power systems. Some bench-top equipment allows training in basic- and electro– pneumatics.

Materials Testing Laboratory

Facilities in the lab allow the students to perform tensile, compression, shear, bending, creep, impact, beam deflection torsion and rotating fatigue tests. Nondestructive test equipment for fluorescent penetrant and magnetic particle inspections equipment are also available.

Metallurgy Laboratory

Facilities in the lab allow the students to perform sample preparation for microstructure examination by optical microscope on ferrous and non-ferrous metals; to carry out various heat treatment processes.

Metrology Laboratory

This lab allows the students to be trained in mechanical measurement and inspection. It is equipped with a variety of measuring tools, universal measuring microscope, profile projector, gear and thread inspection tools, surface roughness tester, computer controlled surface measurement system, computer controlled roundness measurement system, etc.

CAD Laboratory

It hosts a network of computers, printers and plotters, to assist training in technical drawings using AutoCAD and Inventor software.

Basic Skill Workshops

The bench work and sheet metal workshops provide entry-level hand-skills in marking, filing, sawing, drilling, and sheet metal work.

Plant Maintenance Workshop

Facilities in the workshop allow practical hands-on training in the use of common hand- and power-tools; maintenance of valves, bearings, mechanical transmission systems, packing and seals; training in shaft alignment, etc.

Pump and Compressor Workshops

These workshops allow extensive training in operation and maintenance of generic pumps and compressors. A multi-pump test rig and a fully instrumented compressor unit allow performance studies of the generic machines.

Power Generation Workshop

The facilities in the workshop allow studies in vapor power cycles using an oil-fired steam power plant which comprise a high pressure boiler, super heater, turbine, condenser, cooling tower and the feed water treatment units A gas turbine unit comprising compressor-turbine assembly, combustion chamber, power turbine, ignition system and instrumentation enables tests to be carried out on the performance of the machine. A self-contained diesel engine unit fitted with dynamometer, gas analyzer and instrumentation allows studies in diesel power generation.

Diesel Workshop

The workshop contains a number of industrial diesel engines of popular makes that allow rigorous practical hands-on training in operation and maintenance of diesel engines.

Special Program Workshop

Equipped with multi-skill facilities, this workshop enables hands–on training in the use of hand and measuring tools, pipe and pipe threading machines, and valve testing; demonstration of construction, and maintenance of basic industrial equipment such as pumps, compressors, valves, and gear boxes.

Lathe Workshop

Facilities in the workshop allow the student to have extensive hands-on machining experience in turning and shaping.

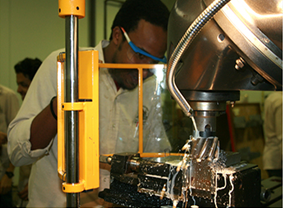

Milling and Grinding Workshop

Facilities in the workshop allow the student to have training in universal milling, surface grinding, tool grinding and high quality surface finish.

Arc and Gas Welding Workshops

These workshops provide extensive training facilities in shielded metal arc welding, TIG, MIG, oxyacetylene welding and cutting, brazing, auto-manual flame cutting, pipe profilers, etc.

CNC Workshop

Facilities in the workshop allow the student to have training in Computer Numerical Control machines for turning and milling. The machines are linked to the CAD Lab, which allows CAD drawings to be sent to the floor mounted machines. Students learn to program simulated machining using standard CNC software.

Refrigeration and Air-Conditioning Workshop

Facilities include benches for tube fitting and welding, flaring, leak testing, system evacuation and recharging, domestic and commercial refrigeration simulators, commercial refrigeration unit with fault simulations, etc.

It allows training in troubleshooting and maintenance of air-conditioning equipment such as room air-conditioners, packaged roof top units, mini split units, etc. The workshop is well equipped with domestic and commercial air conditioning simulators, industrial air conditioning controls, etc.

Senior Project Laboratory

The laboratory is equipped with workstations where the software installed enable the students to undergo mechanical systems design experience, which integrate the mechanical engineering curriculum. Contemporary engineering design, analysis and programming packages are installed for students to complete design assignments and projects in various mechanical engineering areas.